Our Process

Our Process

Listening, Learning, & Asking The Right Questions

We begin with people. Every project starts by engaging with clients, collaborators, and end users to discover the needs and opportunities that will guide our work. Research, dialogue, and observations lead us to the insights that spark great design.

Clarity from complexity.

We partner with clients and teams to turn the wonder of being able to make anything into the confidence of creating the right things. We distill insights into clear goals, align with stakeholders, and chart the path forward, balancing vision with feasibility and creativity with purpose, while collaborating every step of the way.

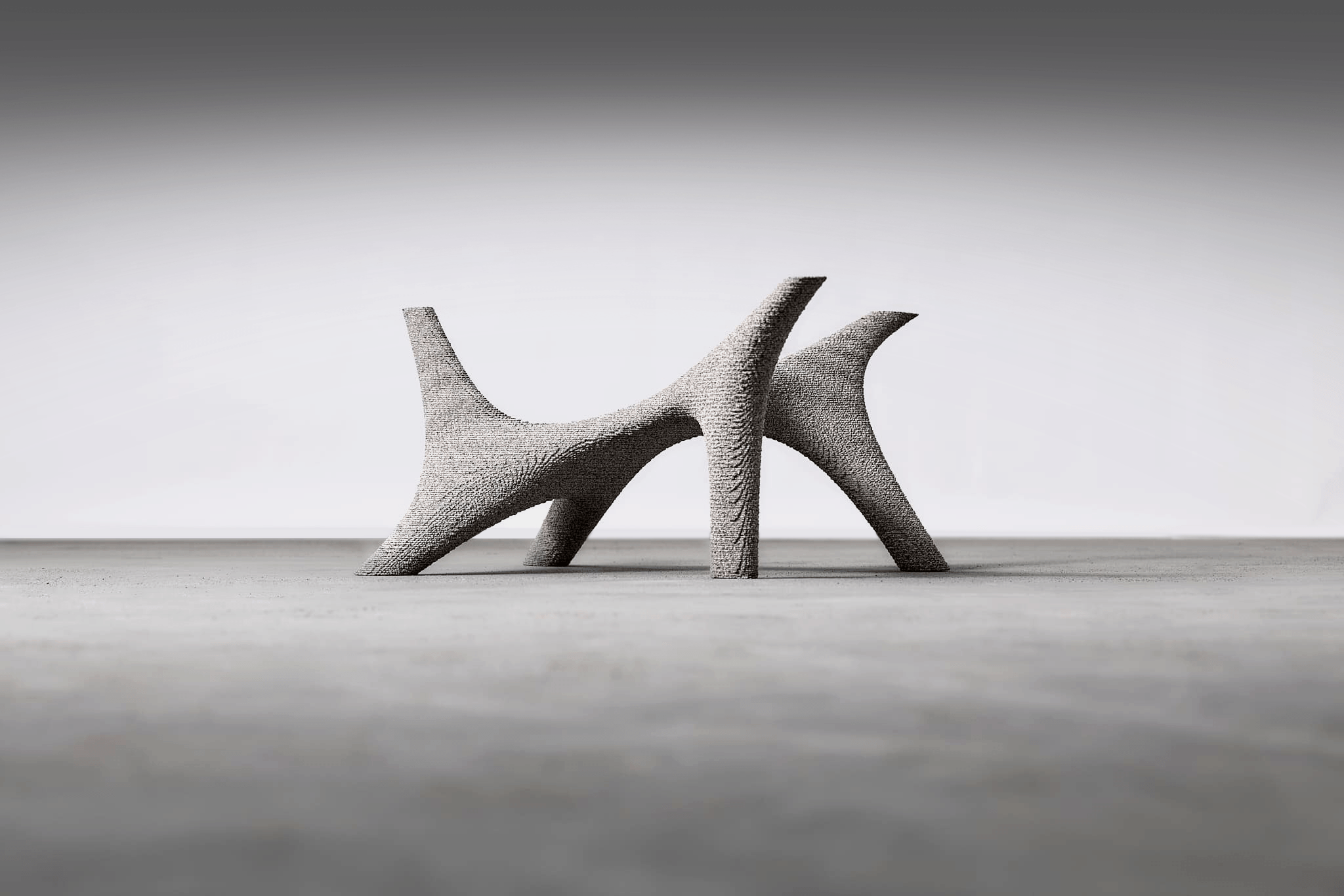

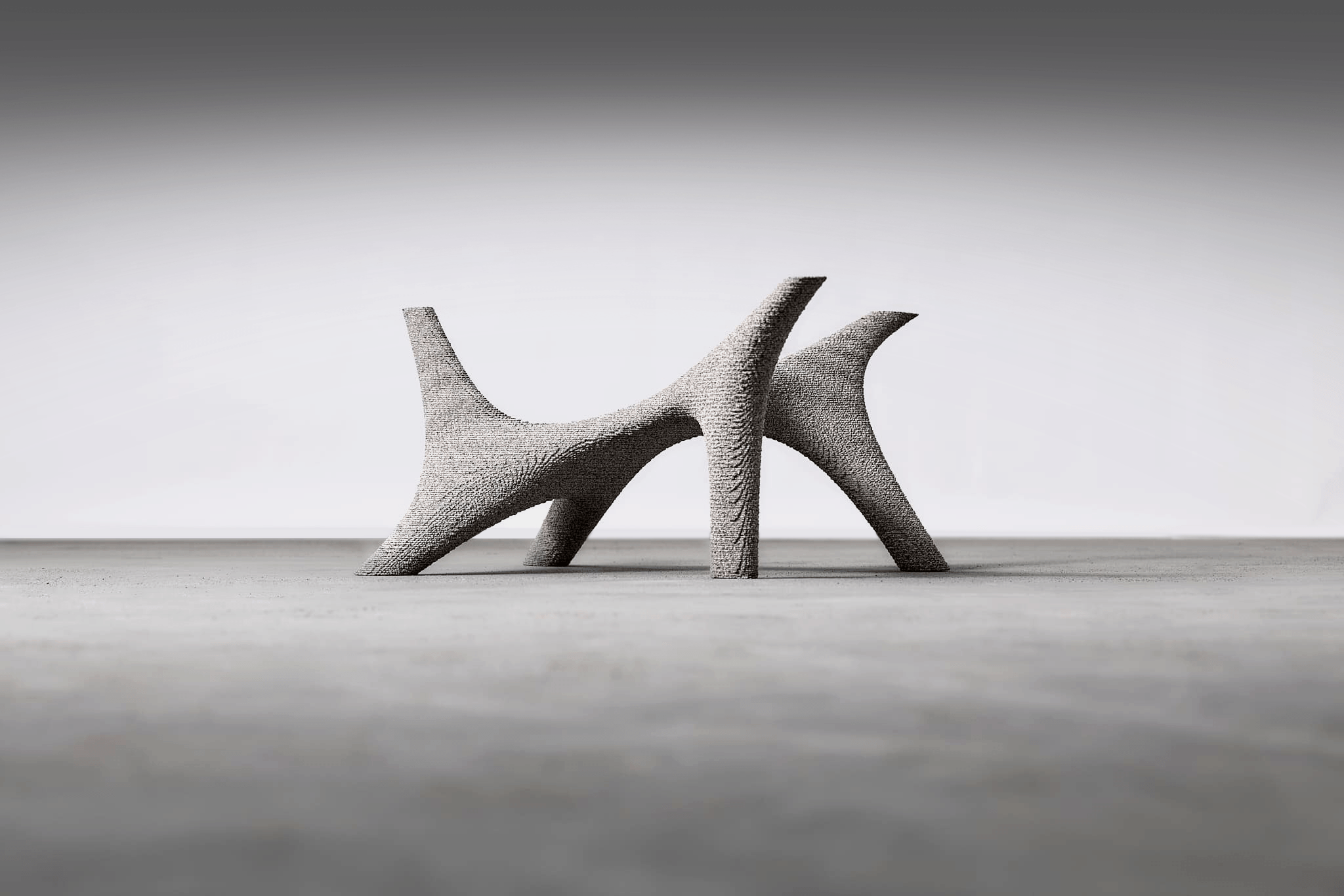

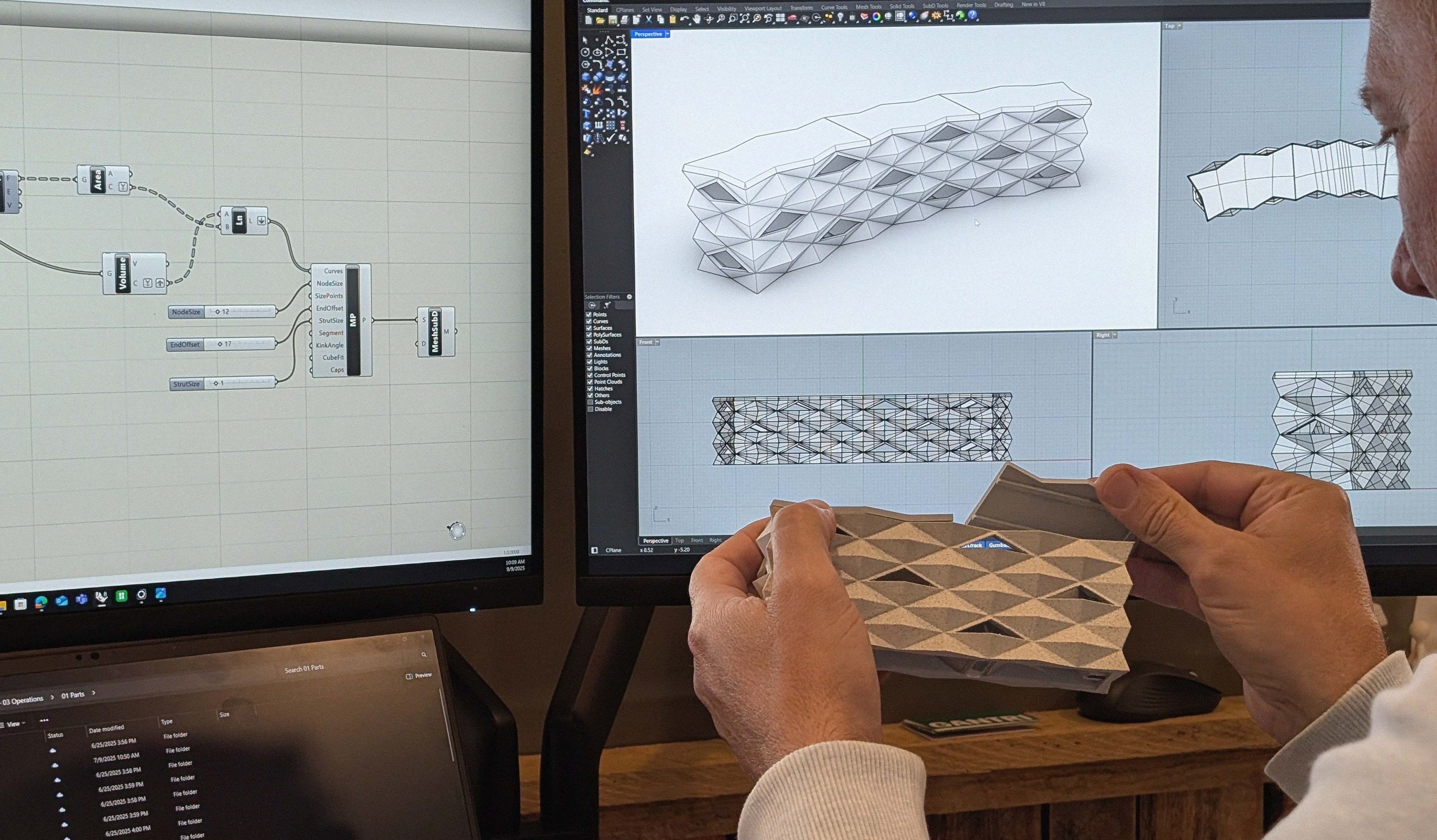

Sketch, Model, Prototype, Test, Iterate.

Here, concepts begin to take shape. We sketch, model, and prototype, testing and iterating our way to unique pieces that are as functional as they are beautiful. Our design expertise and technology converge to push the boundaries of concrete, tell powerful stories, and elevate experiences.

Concrete, reimagined.

This is where vision becomes reality. Our Additive Manufacturing method, SPI (Selective Paste Intrusion), injects cement paste into 2.8mm layers of sand, creating concrete parts unlike anything else. The first of its kind in North America, the magic of this process takes place in a print box measuring 16ft x 8ft x 5ft at our headquarters in Caledonia, MI. If you'd like to see our printer firsthand, or see your design take shape in real time, contact us to schedule a tour.

Finally, each piece is finished, assembled, and delivered with care.